Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

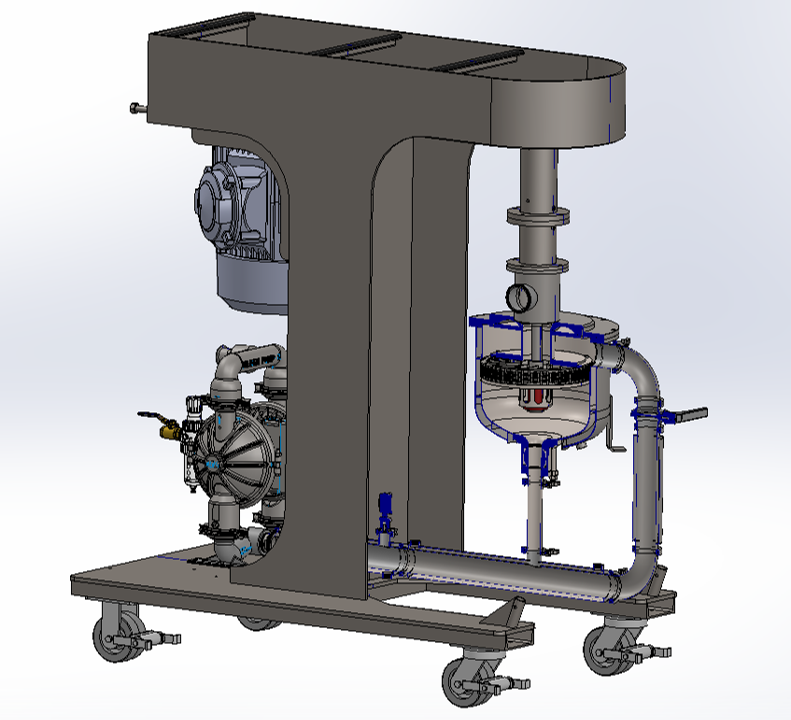

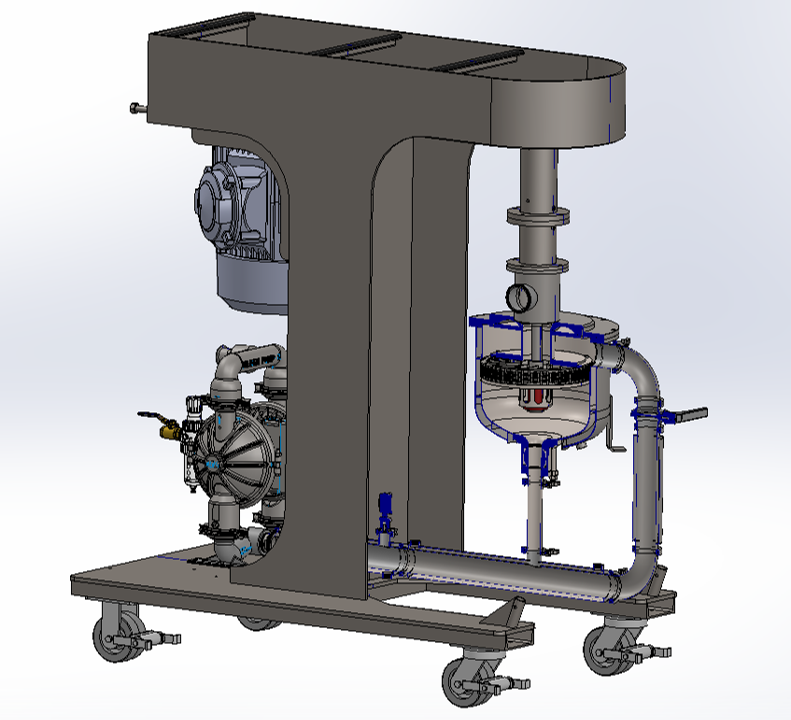

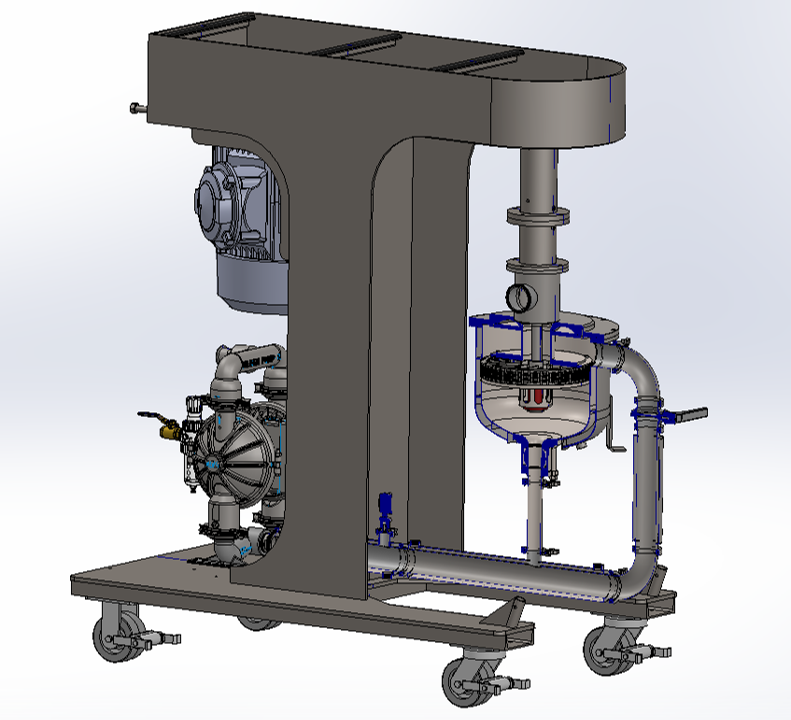

NEXGEN™ Vacuum Rotor Stator

This innovative RotorStator design produces an airless ultra-fine dispersion using an aggressive multi-prong approach to particle size reduction.

Bridging the gap between milling and dispersion, the NEXGEN™ Vacuum Rotor Stator was designed for maximum dispersion. This innovative design with integrated vacuum delivers fast & pure dispersion — NO AIR, NO FOAM... 100% PRODUCT.

Features & Specifications

DISPERSION TECHNOLOGY. FAST. PATENTED

The process takes place in a temperature-controlled environment to preserve formulae characteristics and function. A thorough cooling system covering the chamber and return lines quickly mitigates the heat generated by the aggressive shear forces. The result is a deaerated dispersion, a narrow particle size distribution band, volumetric accuracy, and an optimal dispersion pre-mix for milling into the nanoparticle size range. It easily hooks up to your existing process tanks. Flexible, portable design. Easy cleanup and changeovers.

Vacuum

The air inside the agglomerates expands and forces the particles apart, exposing maximum particle surface area. Liquid and resin encapsulate each particle for fast and thorough wetting.

Controlled Cavitation

The rapid pressure change inside the vacuum chamber creates micro vapor cavities in the liquid. When these short-lived vapor cavities (bubbles) collapse, they generate a shockwave through the feedstock that further aids in particle size reduction.

Extreme Shear Zone

The Interlocking ‘H’ Stator Design creates a unique shear pattern of vertical and horizontal slots for ultra-dynamic impact while offering maximum open area for the greatest flow. The tight tolerances between the rotor and the stator create a short distance between particle acceleration and point of contact for the greatest shattering effect on agglomerates.

Dual Pumping Rotor Design

The NEXGEN™ Vacuum Rotor Stator is pulled from both the rotor’s top and bottom, doubling the number of collisions per particle.

High-speed Recirculation

~300 gpm. The feedstock is recirculated through the shear zone at high velocity to maximize the number of passes for every drop.

Powder Incorporation

Direct powder incorporation into the liquid stream using an eductor that controls the flow and creates a venturi effect. This generates suction at the bottom of the funnel pulling powders into the flow. The high-speed jet coming out of the eductor mixes the powder and liquid before it reaches the rotor-stator.

This innovative RotorStator design produces an airless ultra-fine dispersion using an aggressive multi-prong approach to particle size reduction.

Bridging the gap between milling and dispersion, the NEXGEN™ Vacuum Rotor Stator was designed for maximum dispersion. This innovative design with integrated vacuum delivers fast & pure dispersion — NO AIR, NO FOAM... 100% PRODUCT.

Features & Specifications

DISPERSION TECHNOLOGY. FAST. PATENTED

The process takes place in a temperature-controlled environment to preserve formulae characteristics and function. A thorough cooling system covering the chamber and return lines quickly mitigates the heat generated by the aggressive shear forces. The result is a deaerated dispersion, a narrow particle size distribution band, volumetric accuracy, and an optimal dispersion pre-mix for milling into the nanoparticle size range. It easily hooks up to your existing process tanks. Flexible, portable design. Easy cleanup and changeovers.

Vacuum

The air inside the agglomerates expands and forces the particles apart, exposing maximum particle surface area. Liquid and resin encapsulate each particle for fast and thorough wetting.

Controlled Cavitation

The rapid pressure change inside the vacuum chamber creates micro vapor cavities in the liquid. When these short-lived vapor cavities (bubbles) collapse, they generate a shockwave through the feedstock that further aids in particle size reduction.

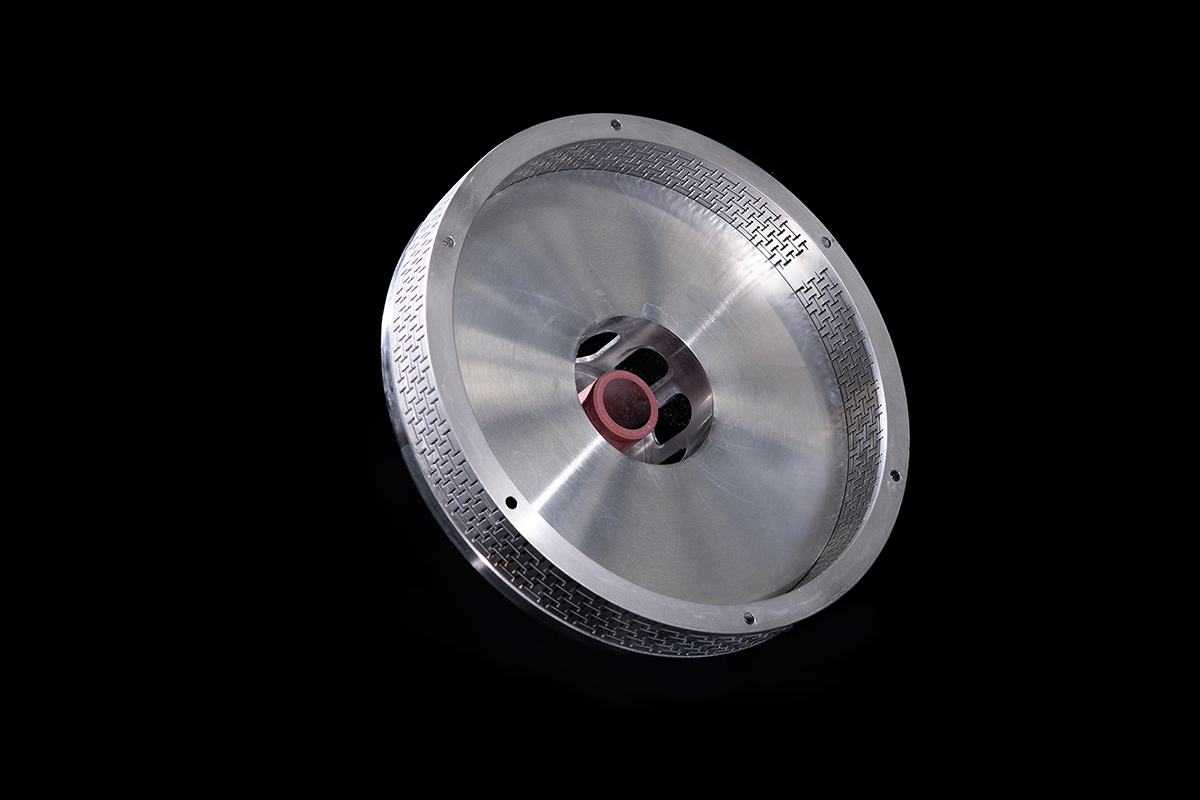

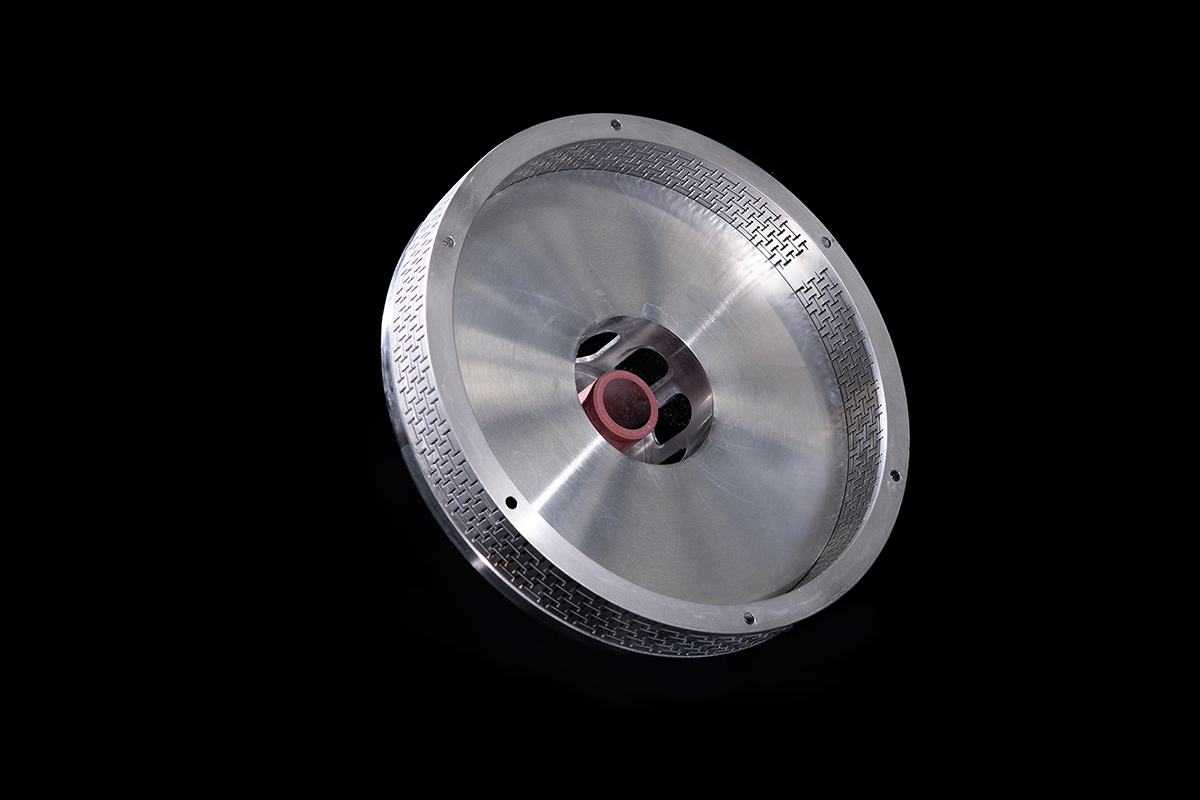

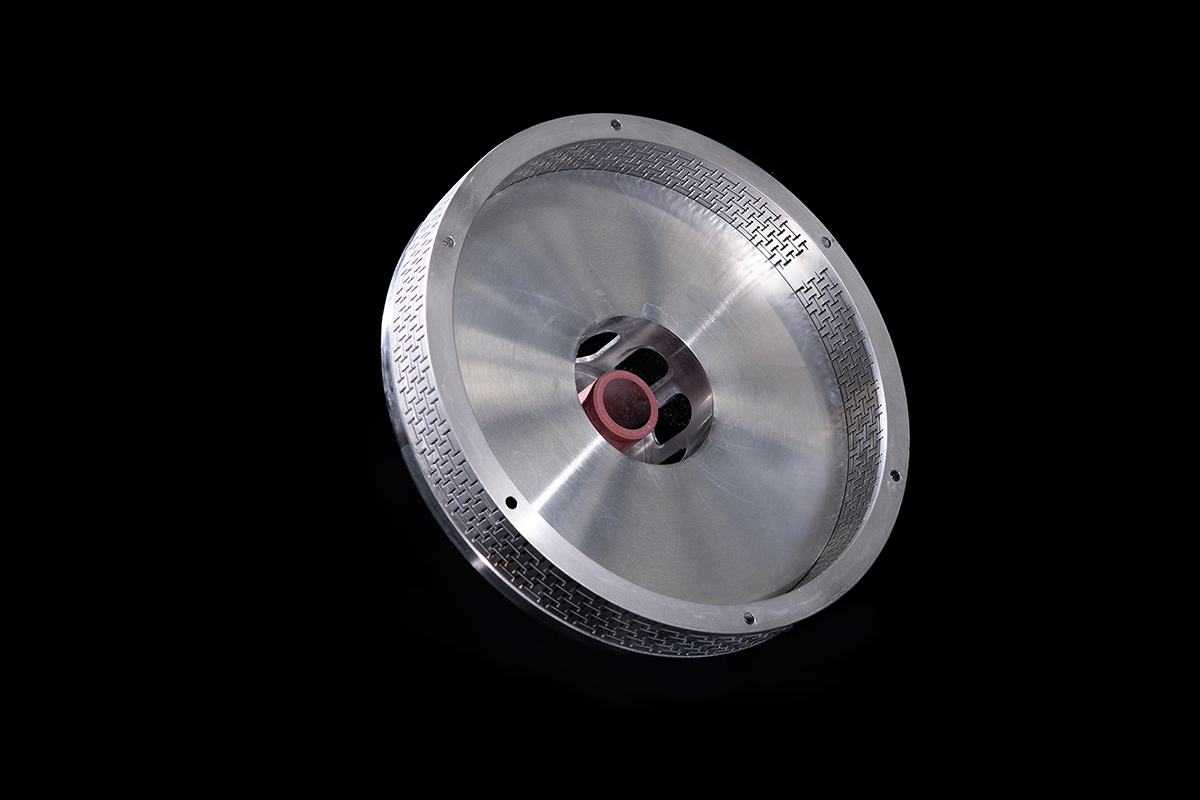

Extreme Shear Zone

The Interlocking ‘H’ Stator Design creates a unique shear pattern of vertical and horizontal slots for ultra-dynamic impact while offering maximum open area for the greatest flow. The tight tolerances between the rotor and the stator create a short distance between particle acceleration and point of contact for the greatest shattering effect on agglomerates.

Dual Pumping Rotor Design

The NEXGEN™ Vacuum Rotor Stator is pulled from both the rotor’s top and bottom, doubling the number of collisions per particle.

High-speed Recirculation

~300 gpm. The feedstock is recirculated through the shear zone at high velocity to maximize the number of passes for every drop.

Powder Incorporation

Direct powder incorporation into the liquid stream using an eductor that controls the flow and creates a venturi effect. This generates suction at the bottom of the funnel pulling powders into the flow. The high-speed jet coming out of the eductor mixes the powder and liquid before it reaches the rotor-stator.